Summary

1111111111111111111111

Summary

1111111111111111111111

2016

2017

2019

Initiated in 2013, the Jazan Economic City (JEC) is a flagship development by the Saudi Arabian government. Located approximately 80 kilometers from Jazan city, the planned city spans 103 square kilometers with an 11-kilometer coastline and a total investment of USD 25 billion. As a key project under China's Belt and Road Initiative in the Middle East, JEC integrates oil refining, power generation, shipping, administrative, and residential zones. It is planned to host a refinery with a daily capacity of 400,000 barrels of standard oil, along with a supporting power plant, making it a pivotal driver of economic growth along Saudi Arabia’s Red Sea coast.

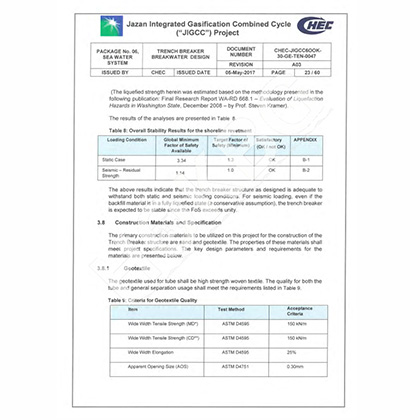

Construction initiated in 2014, materials supplied in 2017

CHEC (China Harbour Engineering Company Ltd.)

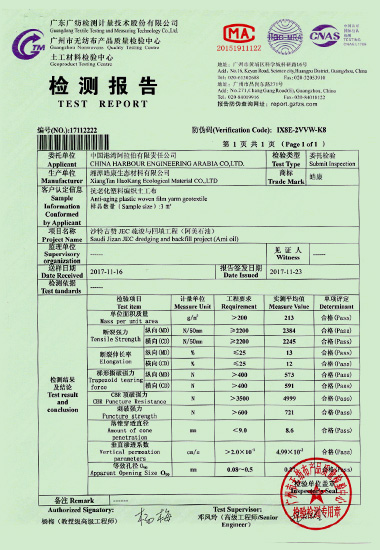

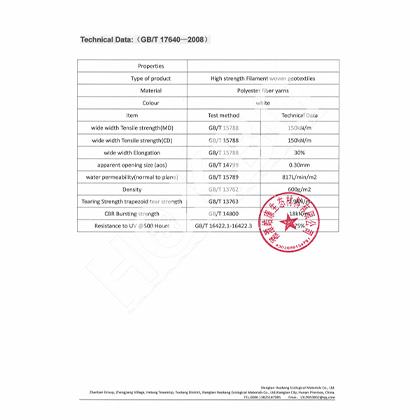

The project employed high-strength, UV-resistant woven geo tubes filled with dredged marine sand, layered and stacked to form perimeter tanggul. These structures were further reinforced with rubble masonry for permanent shoreline protection. The reclaimed area was then backfilled with dredged sand.Geotextile materials were required to withstand the following site conditions (Daily UV exposure of 10–12 hours,Surface temperatures ranging between 50℃ and 80℃) :

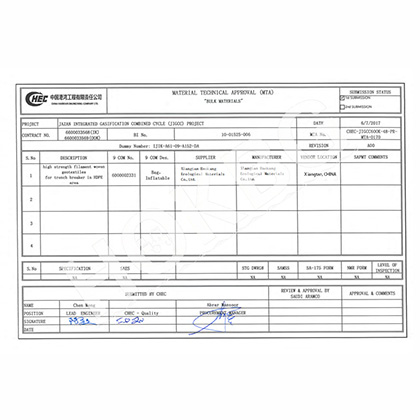

In 2017, our company supplied geosynthetic materials to CHEC for this project:

Photo source: HOKBG

Photo Source: China Communications Construction Company official website

Throughout the project, all mechanical properties of our woven geo tubes met the design requirements. The materials successfully withstood the harsh climate conditions at the site and received high recognition from both China Harbour Engineering Company and the project owner.

2016

2017

2019

The Jazan Integrated Gasification Combined Cycle (JIGCC) seawater intake and outfall pipeline project is part of Saudi Arabia’s Jazan Economic City initiative. Its purpose is to supply seawater for industrial applications such as cooling, desalination, and fire protection, as well as to discharge treated wastewater into the deep sea.

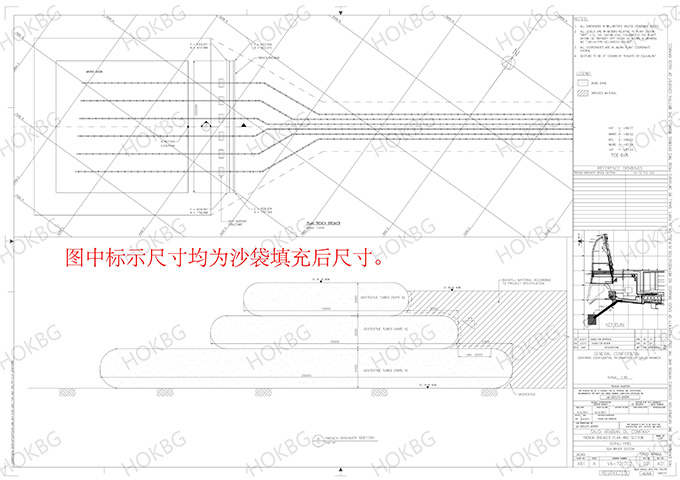

The project features the largest-diameter HDPE subsea pipeline installation in the world, with a total length of approximately 6,600 meters and a pipe diameter of 3.5 meters, capable of delivering 530 million liters of seawater per day.

China Harbour Engineering Company Ltd. (CHEC)

CCCC Water Transportation Planning and Design Institute Co., Ltd.

CCCC Fourth Harbor Engineering Co., Ltd.

CCCC Tianjin Dredging Co., Ltd.

After the large-diameter and ultra-long HDPE drainage pipe was transported to the designated sea area, it was sunk into the foundation trench excavated on the seabed. The design and construction team designed and used high-strength geotube bags. After the geotube bag is filled with sea sand, a large volume of the overall structure is formed, covering the top of the drainage pipe sunk into the foundation trench, preventing the anchoring of ships at sea or the trawling of fishing boats from damaging the drainage network laid in the foundation trench.

The geo tubes were required to have:

Photo Source:HOKBG

Throughout the project lifecycle, the geo tubes supplied by HOKBG met or exceeded all mechanical and environmental specifications. The materials performed well under the region’s extreme climate conditions and received high praise from both the general contractor (CHEC) and the project owner.